The CrystAPC project ended on December 15, 2023. On this occasion, the entire team gathered to summarise the results of the project and discuss further research and application of the results as well as commercialisation.

We would like to thank all project participants and everyone who supported the realisation of this project.

On December 14, 2023 our research group visited the Faculty of Food Technology in Osijek. Prof. Ačkar, Vice Dean for Science and International Cooperation, was our host. Our group presented the CrystAPC project and gave an overview of the project objectives, approach and current scientific achievements. Professor Ačkar presented the faculty's diverse scientific efforts and shared with us research experiences in the field of food technology.

The meeting ended with a discussion on possible future collaboration and knowledge dissemination between the two institutions.

On December 7, 2023, our team visited the University of Applied Sciences FH Campus Wien. The FH Campus is renowned for its close connection to industry, which allows students to gain practical experience and get directly involved in research.

During our visit, we had the pleasure of meeting Prof Michael Maurer and his colleagues, who showed us around the classrooms and laboratories of the Bioengineering Department. During the lab tour, a wealth of information and experience was exchanged between the research groups, increasing the potential for future collaboration.

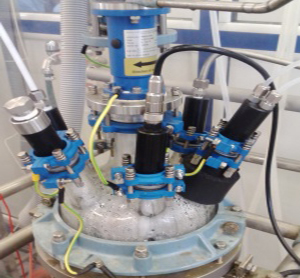

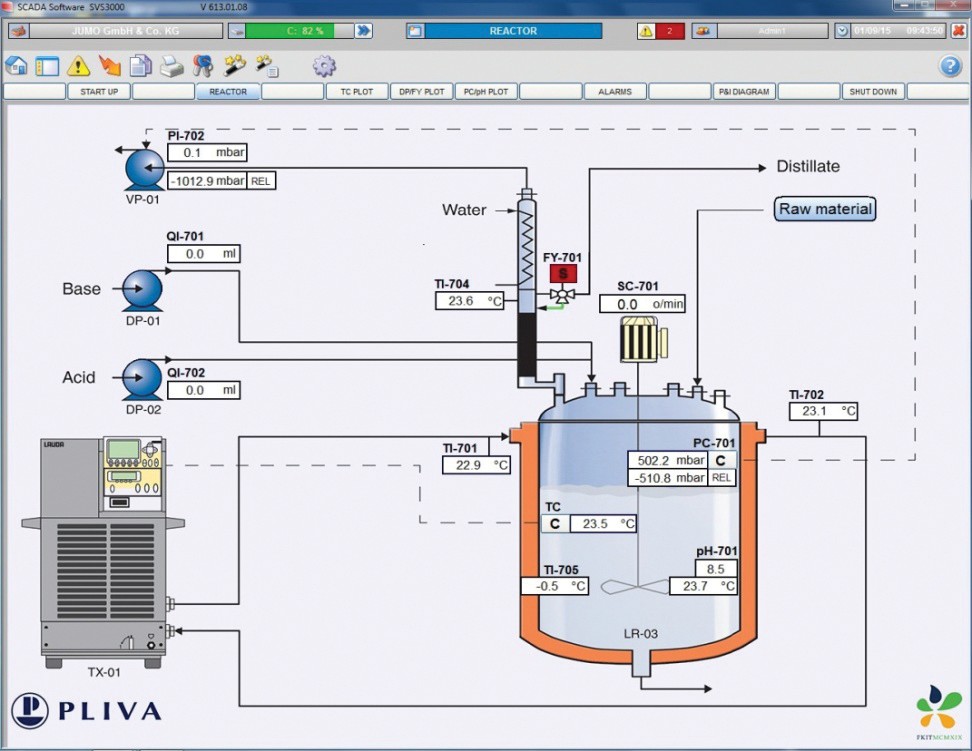

CWT, a spin-off company of the Faculty of Chemical Engineering and Technology, has built a CCS (Carbon Capture and Storage) pilot plant in collaboration with our department on behalf of the South Korean company Carbon Value Co. Our researchers M. Markić, M. Sejdić and J. Sacher were responsible for the integration of the measuring equipment as well as for the PLC programming and the SCADA interface for the process control of the pilot plant. The operation of the plant was demonstrated during the visit by experts from South Korea. The pilot plant will be delivered to South Korea after the final system tuning and optimisation. We expect further joint projects and cooperation in the near future.

We visited one of the largest automation trade fairs SPS which took place in Nuremberg from 14 to 16 November 2023.

The SPS trade fair covers the entire spectrum of the smart and digital automation industry, including state-of-the-art automation technology.

We established contacts with manufacturers of measuring devices (spectrophotometric and gas analysers) that are relevant to our current and upcoming projects.

On November 15, 2023 we visited the Siemens production facility for process control units in Karlsruhe, focusing on the "matrix" production model. In the Process Automation World (PAW) demonstration and exhibition centre, we were introduced to the latest Siemens technology. After the presentation of Siemens' state-of-the-art automation concept, Professor Bolf presented the possibilities, project results and industrial references of the Faculty and the Laboratory for Automation and Measurement.

We would like to thank Mr. Inoslav Lončarević for his efforts in the organisation and presentation, as well as for the pleasant company and the opportunity to meet the top management of Siemens.

On November 14, 2023 we visited Höchst IndustrialPark and Provadis Hochschule.

During our visit to Provadis Hochschule, we learned more about the study and vocational educational programmes with strong links to the chemical industry and R&D within the industrial park (23,000 employees). We took a tour of the chemistry laboratories and pilot plants with a presentation of current projects.

Siemens AG at Industriepark Höchst provides high-quality engineering and consulting services for process industry customers. We are introduced to current projects in the chemical engineering department and involved in lively discussions.

Assist. Prof. Ujević Andrijić and Prof. Bolf participated in VIII International Scientific-Professional Symposium “Environmental Resources, Sustainable Development And Food Production – OPORPH 2023” in organization of Faculty of Technology of the University of Tuzla and the Association of Chemists of Tuzla Canton on November 9 and 10, 2023.

We shared our knowledge on process analytical technology as well as our experience with different spectroscopic measurements for in situ concentration measurements in solutions. In the poster section, we presented the study Process Analytical Technology for Real-Time Crystallisation Process Control.

On October 31,2023 we visited HyCentA – Hydrogen Technology Research Center Austria in Graz. The HyCentA is focused exclusively on hydrogen technologies. They conduct research and development projects on the production, distribution, storage and application of hydrogen in the energy sector.

During the conference in Palermo, Italy, from 22 to 25 October, our Department participated with a posterDesign of a laboratory-scale system for the production of green hydrogen based on AEM water electrolysis presented by dr. Herceg.

The presentations on hydrogen production, safety and carbon capture and storage were a very interesting part of the conference. We discussed with potential partners about upcoming projects related to the optimal control of hydrogen production processes.

At the MSV International Engineering Fair in Brno, which took place from 10 to 13 October, the main topics were the digital factory and artificial intelligence. We saw presentations on Digital Factory 2.0, met many exhibitors and learnt about case studies and established several contacts with potential partners.

One topic of Industry 4.0 was the increased networking of industrial companies and their security. Seminars were also organised on advanced and unconventional technologies used in advanced engineering.

On 12 October 2023 the CrystAPC project leader Nenad Bolf and researcher Matea Gavran gave a lecture on process analytical technology and its application in the pharmaceutical industry at the Faculty of Chemical Technology in Split, organised by the Croatian Society of Chemical Engineers – Association of Chemical Engineers and Technologists Split.

Professor Bolf introduced the CrystAPC project and presented the application of process analytical technology in modern process control systems. Matea Gavran presented her research work within the project, in which she outlined the steps in the application of PAT for advanced process control, as well as the problems that can arise and how to solve them.

The presentation was followed by a lively discussion on the application of artificial intelligence and the challenges that new paradigms bring to higher education.

On 21 September 2023, our team took part in the Networking@ Pharma event at Siemens City Vienna.

The meeting brought together experts from the pharmaceutical industry, research institutions and start-up companies. Most of the presentations focussed on digital transformation in the pharmaceutical industry, the application of algorithms in production and the development of digital twins of pharmaceutical plants. Following the presentations, we visited the Siemens Living Lab and exchanged ideas with experts from the pharmaceutical industry, research centres and start-ups.

Nenad Bolf and Marko Sejdić took part in the 6th ECCPM – European Consortium for Continuous Pharmaceutical Manufacturing Forum together with numerous participants from industry and science. The first day was dedicated to training on advanced pharmaceutical production and a laboratory tour with practical demonstrations (end-to-end manufacturing, cognitive automation, personalised manufacturing and SmartLab). The evening was reserved for socialising and networking.

On the second day, a conference was organised with the presentations on the application of PAT and advanced control in continuous pharmaceutical production and on the application of artificial intelligence methods to simulate and control complex processes.

We presented our work with the poster Process Analytical Technology (PAT) for Real-Time Control in Pharmaceutical Production.

Prof. Bolf and research assistant Josip Sacher gave a lecture at the 65th Technical Meeting – EFCE Working Party on Fluid Separations, on June 12, 2023 at the Faculty of Chemical Engineering and Technology, University of Zagreb. The lecture dealt with the topic of process analytical technology (PAT) for real-time crystallisation control.

Following the lecture, the participants of the symposium were shown the Laboratory for Automation and Measurement as well as the principle of PAT and its application on a laboratory scale in the crystallisation reactor.

Research assistant Josip Sacher attended EuroPACT 2023, European Conference on Process Analytics and Control Technology, held in Copenhagen, Denmark, May 7-10 2023. There he presented his work on monitoring supersaturation in crystallisation processes and shared his experiences with other researchers in the field. His research was presented in a paper entitled Use of process analytical technology for monitoring supersaturation during cooling crystallisation of pharmaceuticals.

Within the framework of the 28th Croatian Meeting of Chemists and Chemical Engineers, we organized the workshop Process Analytical Technology in Real-Time Control.

The workshop addressed the practical aspects of PAT and provided participants with a comprehensive understanding of its functionality and limitations.

In the first part of the workshop, industry partners demonstrated the benefits of using PAT in their respective fields. In the second part of the workshop, two case studies were presented on the development and application of PAT for advanced process control.

Our guest lecturers from usePAT, Siemens, Pliva/Teva, and researchers from the Faculty of Chemical Engineering and Technology presented their research and state-of-the-art concepts. At the end of the workshop, a remote connection was established with the Siemens Living Lab in Vienna.

The workshop was aimed to researchers and practitioners in the field of chemical engineering – pharmaceuticals and fine chemistry who would like to learn about the latest developments in chemometrics and process control.

In February and March, we conducted APC-1, APC-2, and APC-3 hands-on training for INA Rijeka oil refinery employees.

Participants gained knowledge of basic and advanced methods of process control, as well as process diagnostics and optimization. During the courses, real examples of refinery processes were analysed interactively with advanced process control simulators. During the training, an interesting discussion developed on the specific problems encountered in industrial production. We thank the engineers of the refinery for the pleasant atmosphere.

On February 28, our team visited the Research Center for Pharmaceutical Engineering (RCPE) in Graz. The RCPE is one of the leading pharmaceutical engineering research institutions in Europe.

We learned about research areas and ongoing projects. We shared our expertise on PAT applications for monitoring and controlling crystallization processes. Then we toured the characterization and analytical laboratory as well as the pilot plant.

This visit was very informative and productive, and we look forward for collaborations with the RCPE under the Horizon and InterReg programs.

On February 21, we visited Politecnico di Torino, one of the best technical universities in Europe. Our host was Prof. Elena Simone and her team.

After the introductory presentations of the research areas, M. Gavran and J. Sacher gave a workshop on modern methods in crystallization research. The workshop covered both theoretical and practical aspects of batch crystallization and provided the participants with the main concepts and techniques in this field.

Following the workshop, we visited the new crystallization and freeze-drying research laboratories recently built on campus.

On January 30 and 31, our team visited the Budapest University of Technology and Economics led by Prof. Botond Szilagyi and his team.

On the first day of the visit, Prof. Szilagyi held a workshop on crystallization modelling and control, where the methods for solving population equilibrium were presented and their application was demonstrated.

The next day was reserved for visiting other chemical engineering research groups at the university. We took the opportunity to exchange research experiences and discuss collaboration for upcoming projects.

In December, we visited the Karlsruhe Institute of Technology (KIT), Campus North. With our friendly hosts we visited the Institute for Biological and Chemical Systems (https://www.ibcs.kit.edu/english/index.php), the Institute for Microprocess Engineering (https://www.imvt.kit.edu/index.php), the Institute for Nanotechnology (https://www.int.kit.edu/) and the Energy Lab 2.0 (https://www.elab2.kit.edu/english/index.php).

An extensive tour of the site provided us with useful insights and contacts with potential future employees.

On the second day, we visited the Siemens Industrial Park with our colleagues, where we discussed the latest digitization concepts in the process industry.

SPS – Smart Production Solutions is one of the largest international automation trade shows. The fair gathers the leading companies of the automation industry from Germany and from abroad. At the very well-attended fair, drive systems and components, control systems, interfaces, sensors, industrial communication and infrastructure, software and information technology in general were showed.

We visited a number of booths and talked to potential partners. Further cooperation was agreed with Aveva and Siemens in the areas of design, advanced process control and development of process analysis technology.

Research assistant Matea Gavran and prof. Bolf participated in a TC24 Chemical Measurements conference organized by the International Measurement Confederation (IMEKO).

We shared our knowledge of process analytical technology as well as our experience with various spectroscopic measurements for in situ concentration measurements in solutions. In the poster section, we presented the paper “In-situ Solution Concentration Measurement Techniques in the Crystallization Process”.

We participated in the Networking @ Siemens Pharma event on September 22, 2022 at Siemens City Vienna.

Prof. Nenad Bolf gave an interesting presentation: Application of PAT &QbD in Crystallization Process Control. Most of the presentations focused on digital transformation in the pharmaceutical industry. After the useful presentations, we visited the Siemens Living Lab and made important business contacts during the networking dinner.

Under the organization of the National Association of Chemists and Chemical Engineers of Spain (ANQUE), the 9th World Congress on Particle Technology (WCPT9) (https://wcpt9.org/)was held in Madrid, Spain. With more than 600 participants from 35 countries, it covered virtually all areas related to particle technology. Our team member Matea Gavran attended and gave an oral presentation in the Crystallization and Precipitation section.

Toulouse Graduate School of Chemical, Materials, and Industrial Engineering (ENSIACET – French: École nationale supérieure des ingénieurs en arts chimiques et technologiques) is one of the largest educational institutions for chemical engineering and technology in Europe.

As part of the networking, we visited the laboratories and held meetings with the head of the chemical engineering laboratory, the head of the crystallization laboratory and the head of the biotechnology laboratory to discuss possible collaboration related to the application of PAT in advanced process control.

We participated with two poster presentations at the 19th Ružička Days, Today Science – Tomorrow Industry conference, held in Vukovar, September 21–23, 2022. Josip Sacher presented the results of his research on determining the optimal cooling profile of a batch cooling crystallizer (PDF).

Željka Ujević-Andrijić presented her research on data-driven estimation of critical quality attributes in industrial processes (PDF).

In the framework of the CeSaR project at the Faculty of Chemical Engineering and Technology undergraduate and graduate students improve their practical and soft skills using advanced software to simulate, optimize and control industrial processes through adapted laboratory exercises.

In our laboratories student can widen their knowledge of process modeling and control, as well as they are introduced to the techniques of process analytical technology (PAT).

During May practical courses with the application of interactive real-time process simulators for Siemens Croatia employees were held at our department.

Participants acquired knowledge of advanced process control, process diagnostics and optimization, as well as process measurements, equipment’s and unit operations. During the courses, real-life examples of industrial processes were interactively analyzed using advanced software packages for real-time process simulations (PiControl Solutions and ChemCad software package).

On April 4th & 5th our team visited Siemens Living Lab and usePAT in Vienna.

Team of PAT experts in Siemens Living Lab introduced us with their concepts and system for PAT tools integration. We presented the CrystAPC project and proposed further possibilities for integrating our research within SIPAT platform.

UsePAT is a startup that develops and produces ultrasonic devices for the improvement of in-line process monitoring techniques. We had a tour of the lab and got to see their technology in use.

Recently we have finished construction and startup of our advanced crystallization laboratory. With the support of Blazemetrics company and laboratory equipment suppliers, we installed the state-of-the-art process microscope for research and development of crystallization processes. Installed Blaze 900 is a laser microscope with integrated Raman optics specialized for particle signal measurement. The device will speed up process development and monitoring by giving accurate data on Raman spectrum of particles, crystal shape and crystal size distribution in real time.

We presented our research at the International Conference XIV Meeting of Young Chemical Engineers held in Zagreb on February 24th and 25th. J. Sacher presented research Improvement of granulometric properties of crystals by constant supersaturation feedback control (PDF). We also presented the posters: Comparison of linear calibration models for predicting glycine concentration (PDF); Fouling deposition monitoring using neural network models with estimated unmeasured process variables in crude oil pre-heat heat exchangers (PDF).

We participated on Croatian Meeting of Chemists and Chemical Engineers held from October 5th to 8th with three poster presentations: Development of the calibration model for real-time measurement of glycine concentration in glycine-water system using ANN (PDF); Influence of antisolvent addition on crystallization kinetics and granulometric properties of fosamprenavir calcium (PDF); Fouling detection in industrial heat exchanger using recurrent LSTM neural network model.

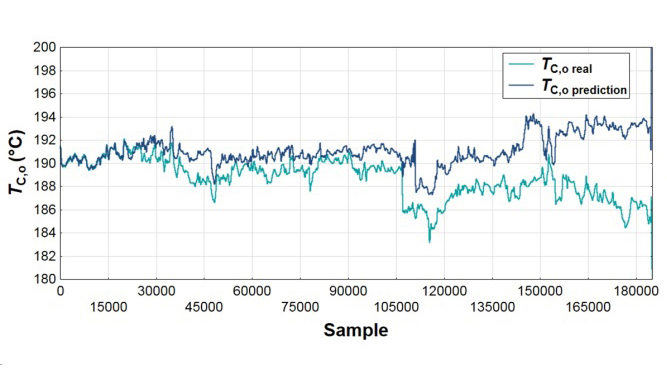

Srečko Herceg, master of mech. eng., successfully defended his doctoral thesis Development of soft sensors for advanced control of isomerization process.

Models were developed for the continual estimation key product quality indicators in a refinery isomerization process using machine learning methods.

Evaluation of the developed models and their implementation in the process control system showed their reliability in estimating of the component contents. The soft sensors will serve primarily as a replacement during the process analyzers’ failure and service periods, as well as it will be a part of advanced control of isomerization process.

On September 29th we visited Rockwool Adriatic factory specialised in production of stone wool, fire, heat and sound insulation for use in buildings and industry.

After introductory presentations we followed with a tour of the production line. A large number of different products and many control loops employed in factory requires good process understanding and coordination.

Our visit initiated a collaboration between the Faculty and Rockwool Adriatic and we accordingly look forward to future cooperation and projects.

A cooperation agreement was signed with the KNOW-Center from Graz, Austria. The collaboration began with a Erasmus remote internship of two of our students on big data project.

We look forward for further cooperation in scientific and professional projects in data-driven business and artificial intelligence application.

In cooperation with experts from Teva TAPI R&D in Zagreb, we have designed and implemented a process control system and software solution that enables continuous monitoring and control of flow chemistry reactors in real time.

The system consists of hardware equipment, devices and a software application for process monitoring and control using a graphical interface with which optimal working conditions are maintained.

The Grant Agreement for the project Cryst APC – Crystallization Advanced Process Control is signed. The project is launched on December 15, 2020, and will run for 36 months.

The purpose of this research is to develop a system that allows continuous monitoring and optimal control of the crystallization process. The developed system will have a wide range of applications - from scientific research to the transfer of technology to semi-industrial and industrial scale.

During the project implementation, state-of-the-art equipment will be installed in our laboratory. We expect this project will remarkably increase the potential of our research and cooperation with the process industry.

During the Covid-19 crisis lock-down (March to May), we installed a brand new laboratory exercise for flow measurement.

The exercise is equipped with variable area, differential pressure and orifice meter, vortex, magnetic, ultrasound transit-time and Coriolis flow transmitters. It also possible to measure and analyse the pressure drop along the piping, as well as the control valve operation.

The set-up is connected to our laboratory control system. In addition, a SCADA system for acquisition, control and subsequent analysis of measurement data has been developed and put in the function.

During the Meeting at the Faculty of Chemical Engineering and Technology in February in Zagreb, we presented three papers. Poster presentations deal with the development of a Calibration Model for Continuous Particle Size Distribution Monitoring, Support Vector Machine-based Soft Sensors for the Isomerization Process and Identification and Prediction of the Fouling Formation in Heat Exchangers.

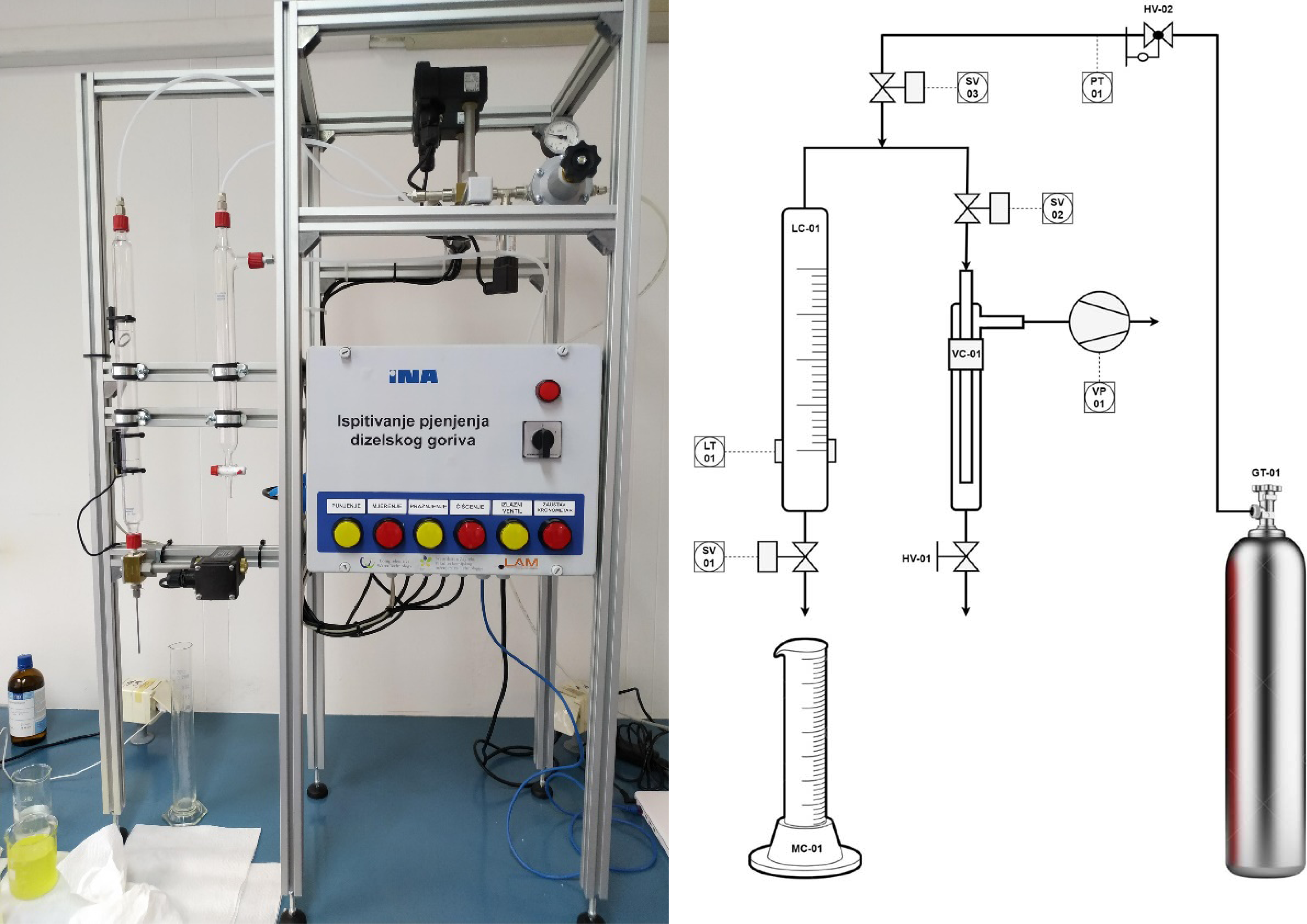

In December we completed and installed system for testing the foaming of diesel fuels at the INA Central Testing Laboratory in Zagreb.

Instruments and apparatus meet the requirements of NF M07-075 standard for testing method. The system is equipped with two photoelectric cells, a pressure gauge, three solenoid valves for control, a vacuum pump, glass beakers and a engraved cylinder.

The electrical cabinet contains a controller and all necessary I/O communication.

Software application is installed to automatically run the experiment and generate testing reports according to the standard.

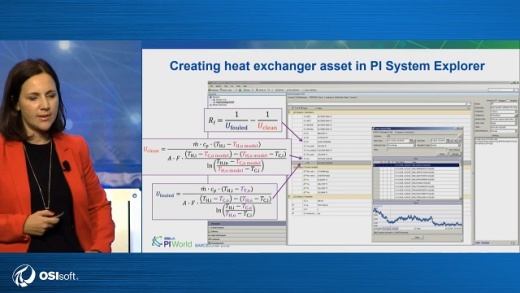

Heat transfer processes are often encountered in the industry and it is necessary to pay attention to the process design and performance.

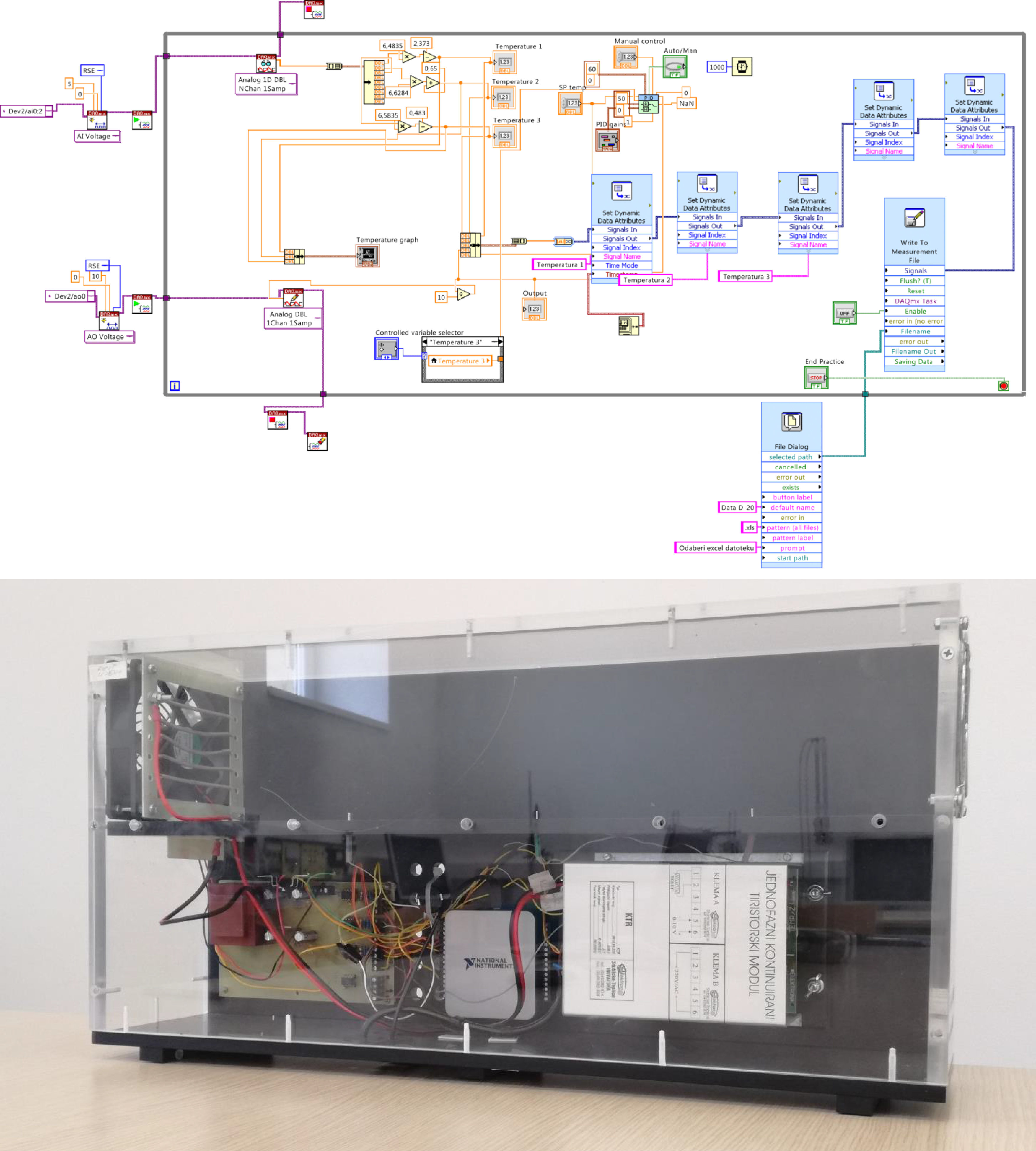

Designed in our laboratory, we install set-up for thermal process dynamics analysis. Dynamic process models are developed based on experimental data to teach the fundamentals of process control and controller tuning.

With the set-up a number of experiments can be performed to determine the static and dynamic characteristics of the process and control loop behaviour. Based on the performed experiments, student now can calculate parameters and optimize the controller performance.

In September we presented our research at the 12th European Congress of Chemical Engineers in Florence. We participated with a poster presentation titled Fouling Detection in Industrial Heat Exchanger Using Neural Network Models as part of the mini symposia: Energy and Chemical Engineering.

The heat exchanger performance is assessed by comparing results of heat transfer coefficient of clean and fouled systems. The performance criteria of developed models together with residual monitoring indicate that the neural networks effectively detect fouling formation.

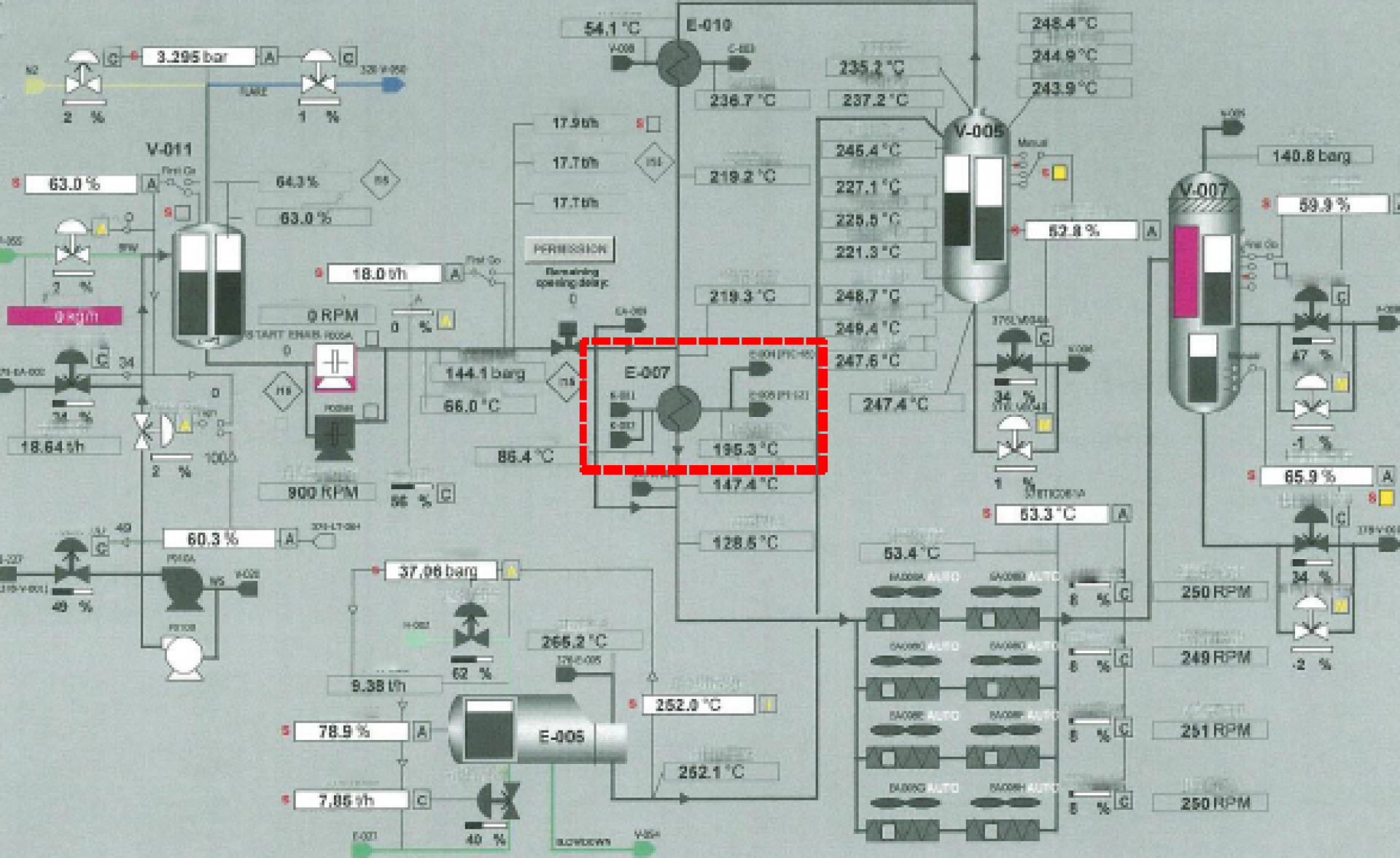

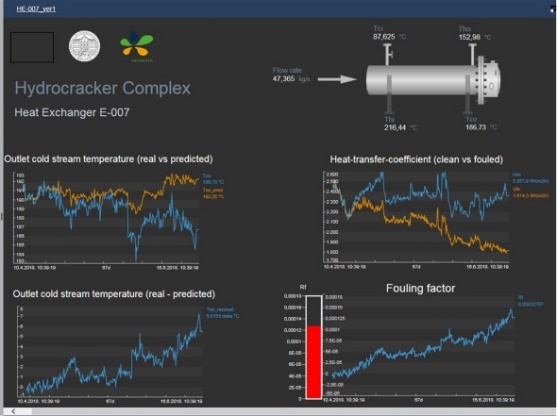

During the first part of 2019, we conducted a pilot project for predictive diagnostics of heat exchangers for INA/MOL Rijeka Refinery.

On-line monitoring system was designed and established for the heat exchanger diagnostics at hydrocracking plant. Machine learning optimized models are developed for predicting degree of fouling. Monitoring system will be used for maintaining operation efficiency and predictive maintenance.

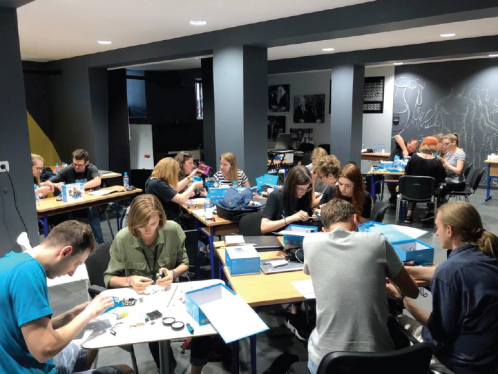

Organized by the Student Section of the Croatian Society of Chemical Engineering and Faculty of Chemical Engineering and Technology (LAM) the Summer School of Robotics was held from July 8 to 10.

During the first day lectures on topic Industry 4.0 were given to introduce participants to the world of robotics, sensors, additive manufacturing and to its application in the industry. Second day, each of the participants had the opportunity to disassemble and assemble simple mBots and become familiar with the programming of robot functions. On the third day of school, the participants were divided into teams and participated in a mini-competition in which they applied the acquired knowledge.

With 30 participants from various institutions, the interest of young professionals was considerable as well as an opportunity for networking and encouraging interdisciplinary work among students.

We spent a useful day at the Siemens Living Laboratory on April 16 in Vienna in company with our colleagues from Pliva/Teva TAPI and our kind hosts.

The Living Lab is a unique pilot plant for the development and demonstration of automation solutions. The focus is on the process industry: in particular the pharmaceutical and chemical industries. In a combination of laboratory, production plant and control room, answers to current questions about Pharma 4.0 are given including extensive discussion on application in the pharmaceutical industry.

The purpose of current project in pharmaceutical API production is to optimize control performance during batch production. The main goal is to improve temperature control strategy in order to optimize overall batch process control. The results are reduced temperature oscillations and optimized heating/cooling sequences which bring improved and easier monitoring and control, a shorter batch run cycle and extends equipment’s service period.

On October 11 & 12 we visited Siemens sites in Karlsruhe and Frankfurt. It was an unique opportunity to see the state-of-the-art process control equipment production and met Siemens expert team to discuss current trends in the process industry and automation. Furthermore, we have visited the Höchst industrial park in Frankfurt with Siemens process and safety engineering laboratories and experienced R&D stuff.

Our visit and contacts are step forward in the cooperation which has already begun in Zagreb by opening our process control laboratory and organizing education and trainings.

OSIsoft EMEA Users Conference was held in Barcelona in September with a series of customer presentations, thematic panels, demonstrations of software tools and interactive workshops. The emphasis was on advanced analytics and machine learning, enterprise infrastructure and business intelligence.

Within the academic session we give a presentation titled Using the PI System in Chemical Engineering Education and Research. The emphasis was on predictive maintenance of the process equipment and our laboratory process control system.

During the event we have established contacts with academic programme stuff and discussed with the PI experts on using of real plant data and solving industrial problems.

In June we were a part of the biggest world forum on chemical engineering and process industry – ACHEMA.

During the event we, jointly with our USA partner PiControl Solutions, gave a presentation titled Multivariable Identification and PID/APC Optimization for Real Plant Application in the section: Plant control and optimization.

The presentation covers closed-loop system identification, controller tuning and advanced process control using simple and affordable software package. The presentation was attended by more than 50 process control specialists, plant managers and other fair visitors.

In cooperation with our partners MKP Ltd. and industrial experts we are developing real-time monitoring and control laboratory crystallization system.

The goal is implementation of PAT (Process analytical technology) techniques to employ real-time measurement of relevant process variables for the crystallization process control (e.g. supersaturation, number of crystal particles, crystal size distribution, polymorphic form). Real-time measurement will allow better understanding of the process and open up opportunity for advanced process control.

Due to reduced energy efficiency caused by fouled heat exchangers in industrial plants there is a need for detection of fouling formation. Models of artificial neural networks for detecting the fouling have been developed. The models are intended for fouling detection and heat transfer coefficient calculation for preventive and predictive maintenance of the industrial shell and tube heat exchangers. By monitoring the efficiency of the heat exchanger, it is possible to systematically plan the maintenance and determine the optimal cleaning time.

In a cooperation with our spin-off company Comprehensive Water Technology (CWT) we designed photobioreactor system for Ruđer Bošković Institute – Center for Marine Research in the town of Rovinj.

Photobioreactors are installed for the purpose of algae production process development under the controlled condition (temperature, pH and light intensity). Produced algae are attended to be used as a raw material for biodiesel production.

CWT designed control cabinet and the photobioreactor set-up, while LAM designed the control system by application of Siemens S7-1200 PLC and PC-station SCADA software. Developed system enables continuous monitoring, control and data acquisition for later analysis and research.

OSIsoft EMEA Users Conference was held in London in October with a series of presentations, thematic panels, demonstrations of software tools and interactive workshops. The emphasis was on big data, IIoT & Industry 4.0, enterprise infrastructure and business intelligence.

Among others we attended the academic session where we discussed with the OSISoft experts the application in students’ education and for industrial cooperation.

We went from the meeting with an enthusiasm and new ideas for application of advanced predictive technology in the process industry for monitoring and analysis of plant and process equipment performance.

Ana-Marija Tomić, Dženita Šola and Andreja Žužić received the Rector's award from the University of Zagreb for their project Analysis and optimizing of plant operation. They have analyzed, diagnosed and optimized control loop performance in the refinery plant.

Fran Jazbec defended his Master’s thesis on Design and simulation of natural gas purification process control in July 2016.

Dominik Načinović presented his Bachelor's thesis on Cement kiln control on September 2, 2017. Dominik has already won one award for his study on self-cleaning concrete.

Luka Tomičak defended his Bachelor's thesis Control valves on September 20, 2017.

Filip Crnković presented his Bachelor's thesis titled Temperature control on September 22, 2017.

Ana-Marija Tomić defended her Master's thesis Temperature control in batch reactors on September 26, 2017. In her work she analyzed, diagnosed and optimized temperature control loops in pharmaceutical batch reactors.

Newly equipped process control laboratory was solemnly opened today at our Department.

After six months of reconstruction the Faculty of Chemical Engineering and Technology in cooperation with Siemens AG and partner company ARP modernized the Laboratory for automation and measurement (LAM).

Within laboratory set-up modern control system with five typical process industry units is put into operation, all supported by the latest generation of SIMATIC PCS7 control system.

The new laboratory in Zagreb offers students, employees and partners the opportunity to train process measurement and control with state-of-the-art equipment.

Using cutting-edge digital systems, the training of future chemical engineers and life-learning education attendants, as well as commissioning engineers and operators, will take place here.

During 2016 we designed the industrial humidification system now applied in pharmaceutical company Eriochem S.A., Argentina. The aim of the project was to design automated system for easy, safe and flexible humidification process. The humidification system includes supply water tank, vaporizer, delivery system and flow/temperature control system. Siemens PLC S7-1200 with HMI control panel is configured for process monitoring, control and data acquisition.

Developed industrial humidification process system enables accurate and repeatable production, safe and efficient process control as well as continuous data acquisition.

In January 2017 we have finished one year-long project at the INA Rijeka Refinery which included:

• Detail analysis, diagnosis and optimization of control loops at 3 groups of plants (GP-1, GP-2 and GP-3);

• Installation and implementation of the modern monitoring and diagnostics system, identification and control loop tuning and simulation software.

350 control loops were analyzed and diagnosed. Based on the historical data control loop models were identified. Ultimately, the control loops were tuned using a high-level optimization tool and their performance was tested in the control room.

As the results 12 newly configured and 32 reconfigured control loops increase automation level of the plants. 30 control loops are switched from manual to auto mode. In 54 control loops we reduced or eliminated oscillation thus increasing the overall plant stability. Sensor or valve problems were detected on 37 control loops. It is estimated that the number of alarms is reduced by 50 %. Finally, variability of the products properties and quality measures are reduced.

We have just initiated large-scale project with the aim to provide monitoring, analysis and tuning of more than 350 control loops at the Rijeka Refinery process units.

Control loop audit will include diagnostics of the field instrumentation and control valves, define sources of variability and oscillation, and poor control loop performance.

The analysis will be foundation for control loops optimization which will result with decreased number of control loops in manual mode, reduced variability of controlled variables and more stable operation.

Additionally, the implementation of the advanced software package will provide a possibility to perform controller tuning education and on-site optimisation.

It is expected after project completion increased productivity, decreased equipment failures and prolonged service time, as well as increased process safety. All mentioned is a good base for advanced process control real application.

The project of laboratory batch reactor automatization and optimisation was carried out during 2015 at the PLIVA R&D department. The aim of the project was to design modern process control system for easy, safe and flexible experimentation.

Developed batch process control system will enable safe and efficient process control, accurate and repeatable experimentation as well as continuous data acquisition for later analysis of experimental results.